Multicore

RM92 solder creams have been formulated as No Clean RMA

type products showing superior resistance to preheat

slump during reflow processes.

- Screen printing and

stenciling grades

- Grades suitable for

fine pitch applications available

- Excellent

resistance to preheat slump

- Good tack

performance and wetting

- Residues may be

left uncleaned

PRODUCT

RANGE

Multicore

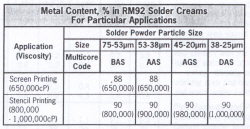

RM92 solder creams may be supplied with powder made from

most solder alloys in the Multicore Product Range. The

most common alloys used are Sn60, Sn62 and Sn63

conforming to the purity requirements of J-STD-006 and

EN 29453. Minimum order requirements may apply to

certain alloys and powder particle sizes.

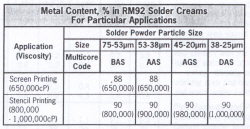

A wide range of metal contents and solder

powder particle size distributions may be ordered but

most applications will be served by the following

recommended products:

For dispensing applications, the equivalent Multicore

RM89 solder creams are recommended.

If clear residues are preferred, the user

should evaluate the Multiprint range. Customers wishing

to print at high speed should consider Multicore RP10

solder creams.

RECOMMENDED

OPERATING CONDITIONS

APPLICATION:

The appropriate grades of Multicore RM92 solder creams

have been specially formulated for application by screen

printing and stenciling. They do not require the

addition of thinners either before use. It is

recommended that products shipped in jars should be

gently stirred for 15 seconds before use.

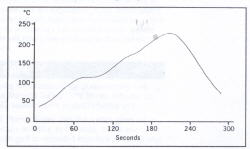

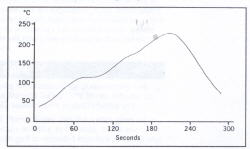

REFLOW:

Any of the available methods of heating to cause reflow

may be used including IR, convection, hot belt, vapour

phase and laser soldering. It is not practicable to

recommend an ideal reflow temperature profile for all

situations. However, the following shows an example

profile which has given good results in practice.

Multicore RM92 solder creams have been

specially formulated to show a marked resistance to

preheat slump. They can tolerate the longer

preheat times often required for large surface

mounted devices or densely populated boards.

Furthermore, Multicore RM92 solder creams are less

liable to char during reflow at the elevated

temperatures required for some solder alloys.

CLEANING:

The residues from

Multicore RM92 solder creams may be left on the PCB in

many applications since they do not pose a hazard to

long term reliability. However, should there be a

specific requirement for residual removal, this may be

achieved using conventional cleaning processes based on

solvents such as Multicore Prozone, or water containing

suitable saponifying agents such as Multicore PC85.

TECHNICAL

SPECIFICATIONS

SOLDER

POWDER: The

solder powder for Multicore RM92 solder creams is

produced by atomising alloys conforming to the purity

requirements of J-STD-006, EN 29453 or other national

and international standards where relevant.

Careful control of production processes ensures that the

solder powder is at least 97% spherical (aspect ratio

< 1.5) and contains less than the minimum level of

contaminants that would adversely affect solder cream

performance. A typical maximum oxide contamination level

of 80ppm (expressed as oxygen in the solder) is

regularly achieved or bettered.

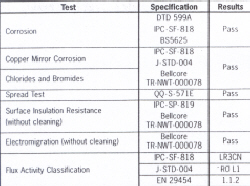

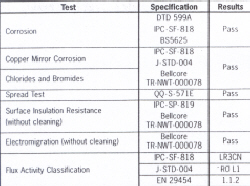

SOLDER

CREAM MEDIUM: The flux for Multicore RM92 solder

creams is a RMA type showing the following

characteristics. Test reports are available on request.

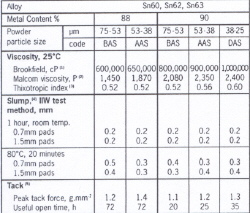

|

|

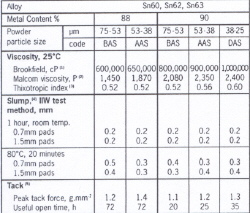

SOLDER

CREAM: The properties of a solder cream depend in

part on the metal content, the solder alloy and the

solder powder particle size range. In general terms,

increasing metal content reduces the tendency to slump

and reduces the tackiness of the solder cream while the

solder balling performance improves. Using solder alloys

with increased density has the same effect as reducing

the metal content.

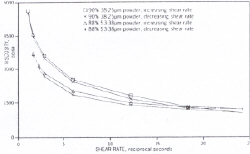

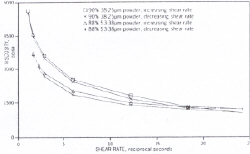

It is common practice to characterise the

rheology of solder creams by making a viscosity

measurement at a single specified shear condition.

Increasing metal content increases the measured value

and at higher metal contents, decreasing the mean solder

powder particle size can have the same effect.

The characteristics of Multicore RM92

solder creams which confer their superior slump

performance also increase their sensitivity to the

conditions of sample preparation before making

Brookfield viscosity determinations. Excessive stirring

before testing can lead to erroneously low values for

viscosity. A more informative indication of the

rheological properties of solder creams is provided by a

plot of viscosity versus shear rate and these typical

results for a selected Multicore RM92 solder cream are

shown in the following graph.

Typical properties of selected Multicore

RM92 solder creams are as follows. Full details of test

methods will be supplied on request.

VISCOSITY

DATA FOR SELECTED MULTICORE Sn62RM92 SOLDERING CREAMS

Measurements made with the Malcolm Viscometer

PACKAGING

CONTAINERS:

Multicore RM92 solder

creams are supplied in:

-

1kg,

500g or 250g plastic jars with an insert to seal off

the surface of the cream

-

1kg

vacuum filled cartridges for direct application

Other

forms of packaging may be available on request.

SHELF

LIFE: Providing

Multicore RM92 solder creams are stored at 5 - 10°C

tightly sealed in the original container, a minimum

shelf life of 12 months can be expected.

Multicore RM92 solder creams have been

formulated to reduce separation on storage to a minimum

but should it occur, gentle stirring for 15

seconds will return the products to their correct

rheological performance.

HEALTH

& SAFETY

WARNING:

The following information

is for guidance only and users must refer to the

Material Safety Data Sheets relevant to specific

Multicore RA10 solder cream products before use.

FUMES,

VAPOURS and PRECAUTIONS: The

flux fumes given off at soldering temperatures are

irritating to the nose, throat and respiratory organs.

Prolonged or repeated exposure to flux fumes may cause

sensitisation.

These materials should always be used in a

well ventilated area and suitable fume extraction

equipment should be used to extract flux fumes away from

the operators.

PROTECTION

& HYGIENE: Suitable

protective clothing should be worn to prevent materials

from coming into contact with the skin and eyes. If the

materials come into contact with the skin, the affected

area should be cleaned with a proprietary skin cleanser

followed by washing with soap and water. If the

materials come into contact with the eyes, they should

be irrigated thoroughly with running water for at least

ten minutes and medical attention sought.

Eating, drinking or smoking should not be

permitted in the working area and hands should be washed

thoroughly before eating.

FIRE

HAZARDS and PRECAUTIONS: The

flashpoint of the solvent used in these materials is

high (127°C) but it is combustible. Carbon dioxide,

foam or dry powder extinguishers are suitable. High

temperatures may produce heavy metal dust, fumes and/or

vapours. Do not use water where molten metal is present.

SPILLAGE

and WASTE DISPOSAL: Spills

of the materials should be scraped up and the

contaminated area washed with water.

Waste materials should be stored in closed

containers and disposed of in accordance with the

relevant local and national regulations.

|